Filling the void for a manufacturer of high-priority military apparatus A combination of RG Group resources and products, resulted in an outcome that met specifications […]

Filling the void for a manufacturer of high-priority military apparatus A combination of RG Group resources and products, resulted in an outcome that met specifications […]

Pneumatics and Creativity Paired for a Powerful Performance RG Group manufacturing and assembly expertise enabled a seamless process to reduce costs, increase productivity and enhance […]

Safety First – Increasing Worker Safety Through Automation Over the past 30 years, there have been only 27 robot-related workplace deaths according to OSHA incident […]

Case Study Categories: Industrial Automation

Robotic Solutions Improve Productivity and Keep Workforce Issues at Bay RG Group’s extensive IA and robotics products and technologies provide solutions beyond point of sale […]

Case Study Categories: Industrial Automation

Automation Expertise Proves a Sound Recipe for this Food and Bev Company With workforce issues disrupting production, RG Group implemented a solution that kept business […]

Case Study Categories: Life Sciences

A World of Solutions for Global Supply Chain and Product Management RG Group developed a cost-saving solution to maximize efficiency and increase ROI Customer/IndustryImmunoassay and […]

Case Study Categories: Life Sciences

Breathing New Life Into Solution Options for This CPAP Manufacturer A combination of RG Group resources and products, resulted an outcome that met government specifications […]

Case Study Categories: Life Sciences

Putting It All Together in One Comprehensive Package A turnkey solution that utilized a full-spectrum of RG Group capabilities, resulted in measurable results across all […]

Case Study Categories: Life Sciences

Putting the Pieces Together with a Diversity of Assembly Options RG Group manufacturing and assembly expertise enabled a seamless process to reduce costs, increase productivity […]

Case Study Categories: Entertainment

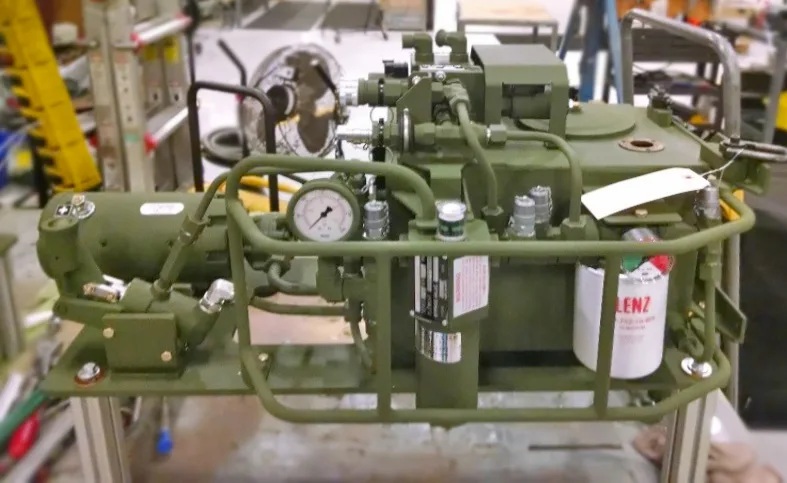

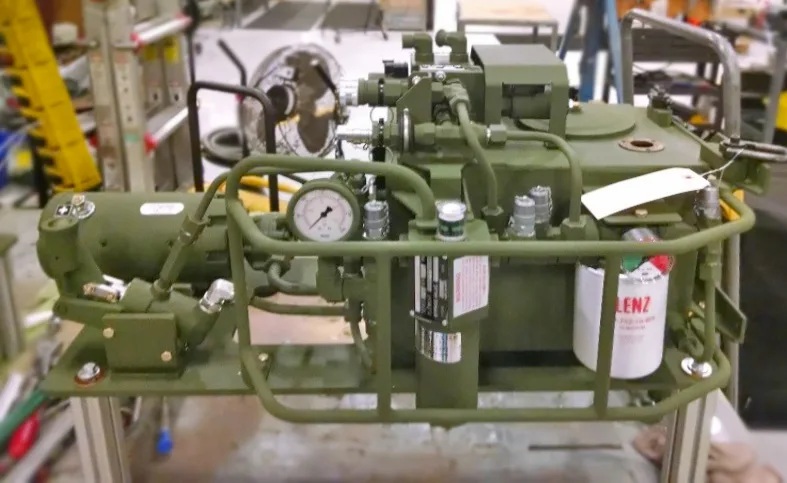

Opportunity: Design and build custom hydraulic system for braking control of large motion simulator. Result: RG Group built and delivered a complete hydraulic system, including […]

Case Study Categories: Entertainment

Opportunity: Design and build custom hydraulic system for moving platform. Result: The RG Team provided a custom control and hydraulic valve system for closed loop […]

Case Study Categories: Industrial Machinery

Opportunity: Design, build and commission an automated testing system to verify the integrity of a high cost medical component for the end-user. Result: RG Group […]

You can count on RG Group for excellent quality and service

Contact us today