Original Article Source Link : Author Mike Poe

This is the final part of our four-part series examining typical logistics processes within in a distribution center (DC). In our last discussion, we explored opportunities to improve operational efficiency and increase throughput for sortation. Today we will focus on outbound logistics.

Increased consumer demand for online shopping has created more pressure on retail distribution and e-commerce fulfillment facilities to deliver products to the right place and on-time to customers and stores, at optimal cost. Outbound orders require more traceability and efficiency of outbound shipping processes to optimize costs and achieve these goals. Reliable and highly accurate machine vision and image-based barcode reading solutions are critical to logistics operations to meet these requirements. Using performance feedback and analytic insights from the these solutions, companies can fine tune their outbound operations to identify problems before they become larger and more expensive. Here are a few examples of typical challenges within the outbound logistics operations and how Cognex solutions help achieve efficiency and cost optimization goals as well as improve traceability.

Optimize shipping costs and enhance revenue recovery

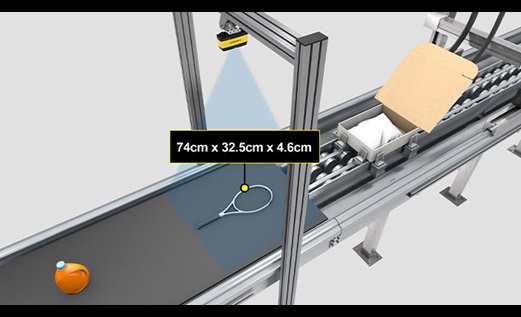

Shipping costs are a large piece of any logistics facility’s operating expenses. To optimize shipping costs, facilities must have the capability to audit the charges they receive for shipping and understand if they line up with expectations based on item sizes. Today, many operations around loading trucks are commonly performed manually. As more products begin to “ship in own container” traditional measuring equipment struggles to provide accurate dimensions on the variety of products which causes extra money to be spent on additional truckloads.

Using a 3D and 2D smart camera, such as the Cognex 3D-A1000 dimensioning system, helps organizations more accurately estimate and lower shipping costs by capturing and providing accurate dimensional and volumetric packaging information to optimize shipping costs and optimize the number of packages per truck. Using 2D image data, the 3D-A1000 helps recover revenue by providing proof of shipment for traceability against damaged or missing claims.

Download Logistics Solutions Guide

Build pallets faster and increase overall truck loading efficiency

Distribution facilities are always seeking more efficient ways to load and unload trucks as the faster they can get trucks in and out of a facility, the higher their throughput. In many cases, packages are manually loaded into trucks and stacked, one item at a time. To meet efficiency requirements, facilities are trending to building pallets prior to outbound shipment as it saves time and money as well as protects product during transport.

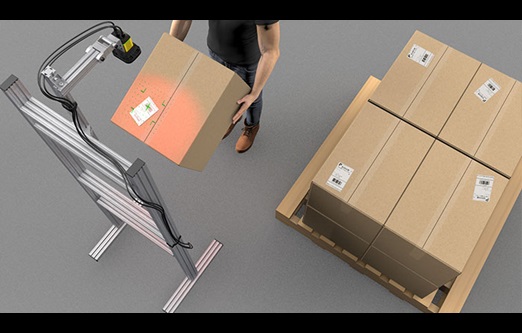

Part of the palletization process involves scanning each item before it is placed on the pallet. Traditionally, laser-based hand scanners are used for this purpose. However, these scanners have difficulty reading damaged or smudged codes, which means operators must take the time to print out a new label for the package which adds time and money to the process. In addition, using a hand scanner requires a free hand, which reduces overall efficiency.

Using image-based overhead barcode reading solutions, such as the DataMan 470 fixed mount barcode reader, offer a hands-free solution to read codes quickly, efficiently, and accurately. The overhead scanning configuration means operators can read and build pallets faster than if using handheld or ring scanners. In addition, this approach ensures distribution or fulfillment facilities ship the correct items, improves inventory accuracy, eliminates costly returns, and improves overall package traceability.

Load outbound trucks faster while increasing traceability and reducing manual handling

Retail distributors and fulfillment facilities are seeking ways to improve traceability from the inbound dock door to the outbound dock door. To achieve “zero loss” of goods as they travel into and through a facility, management teams are becoming increasingly focused on quality of operations and asset management (minimizing loss) so verifying what goes on the outbound truck is more important than ever. In many organizations, operational methods rely on ship sorter accuracy to ensure the right products are loaded on trucks.

However, this approach does not always meet loss objectives. Packages get lost, stolen, or get put on the wrong ship lane due to incorrect sorting due to poor code quality and the scanning system’s inability to read the codes. It is not uncommon for distribution centers to lose several dozen packages per day and tens of thousands over a year. In addition to increased internal costs, customer expectation and brand reputation are negatively impacted when products are not delivered on time or at all.

Many companies use hand scanners as a basic point of traceability at the dock door. This can cause unwanted delays as operators need to take extra time to pick up a scanner, scan a box, put the scanner down, and load the box onto the truck. So, what are your options?

There are a few ways you can improve traceability at the outbound dock door. Choosing the right solution depends on several factors including how many operators your facility requires as part of the outbound logistics process as well as throughput requirements. Operations teams require high accuracy and fast performance from their code reading processes, including the ability to read damaged, smudged, or torn codes. Logistics teams are seeking ways to continually improve the quality of their flow-through operations by using analytics that leverage no-read data and images of unread codes to identify and solve problems earlier in the process, before they become larger and more costly.

– Presentation Scanning at the Dock Door

Using image-based overhead presentation scanning solutions, such as the Cognex DataMan 470 fixed-mount barcode readers, offer a hands-free solution to reading codes quickly, efficiently, and accurately. The overhead scanning configuration means operators can read and load more boxes per minute than if using handheld or ring scanners. In addition, using this application at the dock door ensures distribution or fulfillment facilities ship the correct items, improves inventory accuracy, eliminates costly returns, and improves overall package traceability.

– Outbound Scanning Tunnels

High-volume distribution facilities require fast throughput, higher levels of automation with less operator intervention, and increased traceability. One way to lower the cost of operations is to use multi-sided barcode scanning tunnels, featuring image-based barcode technology such as the Cognex DataMan 470 fixed-mount barcode readers. Using image-based reading technology, you get complete, high-speed barcode reading coverage regardless of the position or condition of the codes. In addition, Cognex barcode scanning tunnels use advanced algorithms and decoding technologies to accurately read codes at extreme angles (up to 85 degrees) to enable packages and parcels to be placed closer together to increase throughput.

As you can see through these application examples, there are plenty of opportunities to optimize areas of your outbound logistics functions for efficiency and throughput. Browse our library of logistics applications and logistics barcode reading systems and tunnel solutions to learn how Cognex image-based barcode readers and machine vision solutions help improve efficiency and traceability, increase throughput, and optimize processes.

In case you would like to read other blogs in this series:

Part 1: 3 Ways to Power Up Your Inbound Logistics Operations

Part 2: 3 Smart Ideas to Boost Your Order Fulfillment Process