Automation/Robotic Solutions

SOLUTIONS

Automation / Robotics

Streamline your operations for lower operating costs, improved performance and increased profits.

At RG Group, we are experts in the latest automation/robotic solutions. Our commitment to providing cost-effective options ensures that you can rely on us to deliver automation solutions that yield measurable production improvements.

The manufacturing industry is undergoing significant changes, especially regarding its technology requirements. Simply using automation and robotics for high-volume production is no longer sufficient. Today, automation must quickly adapt to real-world variability, providing manufacturers with the flexibility needed to respond to constantly changing consumer demands, market trends and shrinking labor markets. In manufacturing, flexibility is now the new speed.

We partner with leading brands in pneumatic and electronic automation components and solutions. Our experienced in-house engineering team has decades of collective experience in designing and manufacturing custom components, as well as pneumatic and electronic control systems tailored to meet our customers’ needs.

Experience firsthand what it’s like to put together an automation project.

Overlooked benefits provided by automating production

- Adaptable, agile solutions to meet diverse production needs

- Eliminates labor issues

- Optimizes throughput

- Technologies that can be integrated for maximum results

- Safe, cost-effective solutions

- In most instances, quick deployment and ROI

Popular automation/robotic solutions

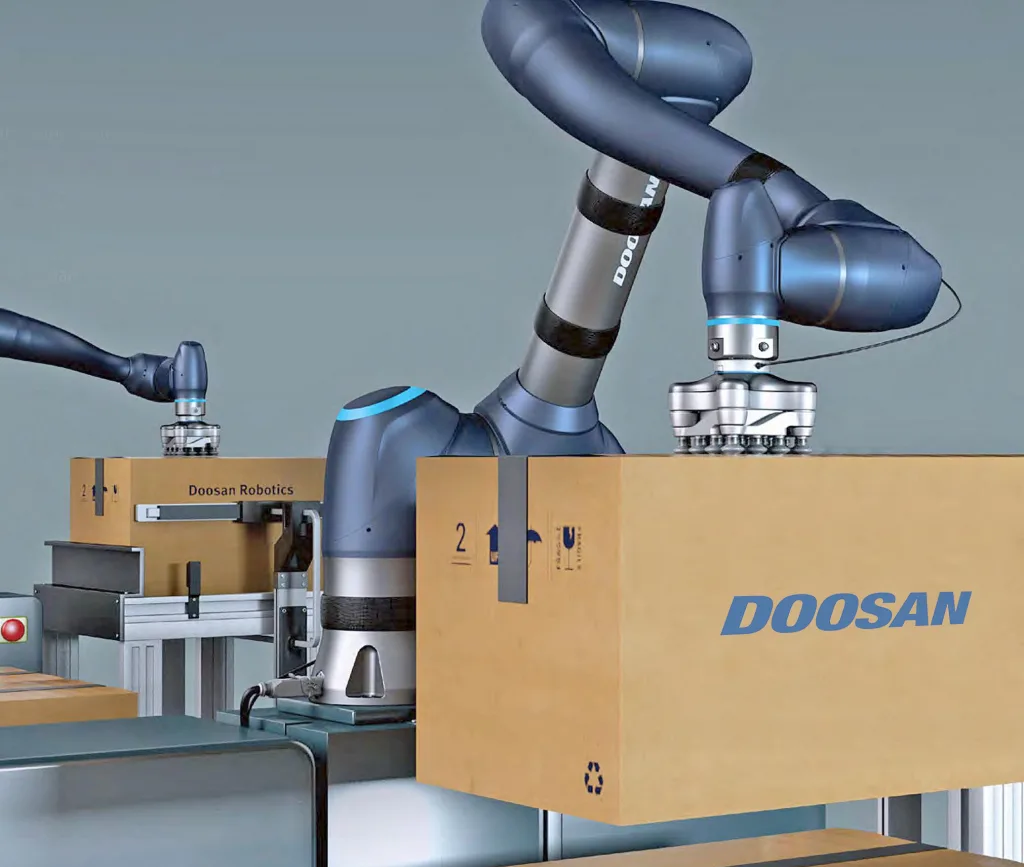

Palletizing

Typically end-of-line operations, stacking cartons/items from conveyor and/or pallets via Robot/COBOT.

Depalletizing

Typically end-of-line operations, stacking cartons/items from conveyor and/or pallets via Robot/COBOT.

Material Handling (Material Transport)

The process of moving materials throughout a facility via an AMR, tug, tow or lift vehicle.

Machine Tending

Robotic machine tending (CNC Machine Automation) is the process of using a robot system to automatically load and unload a production machine.

Line Loading/Unloading

Adding or removing products/materials from a line via an automated process by robot/COBOT.

ASRS (high density storage)

An automated storage and retrieval system consists of a variety of computer-controlled systems for automatically placing and retrieving loads from defined storage locations.

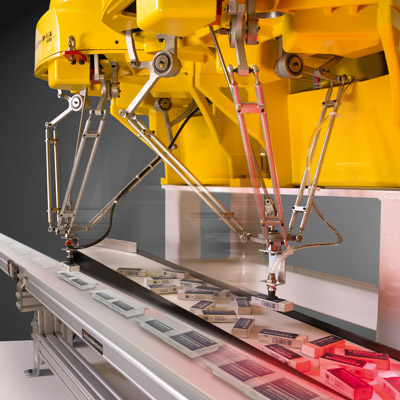

Packaging

Packaging robots are designed to open, fill, transport, palletize, seal, code and/or label product packaging.

Tracking/Traceability

The ability to follow materials entering, moving through and exiting a facility. Typically scanned through a barcode reader and monitored via real-time data via a dashboard.

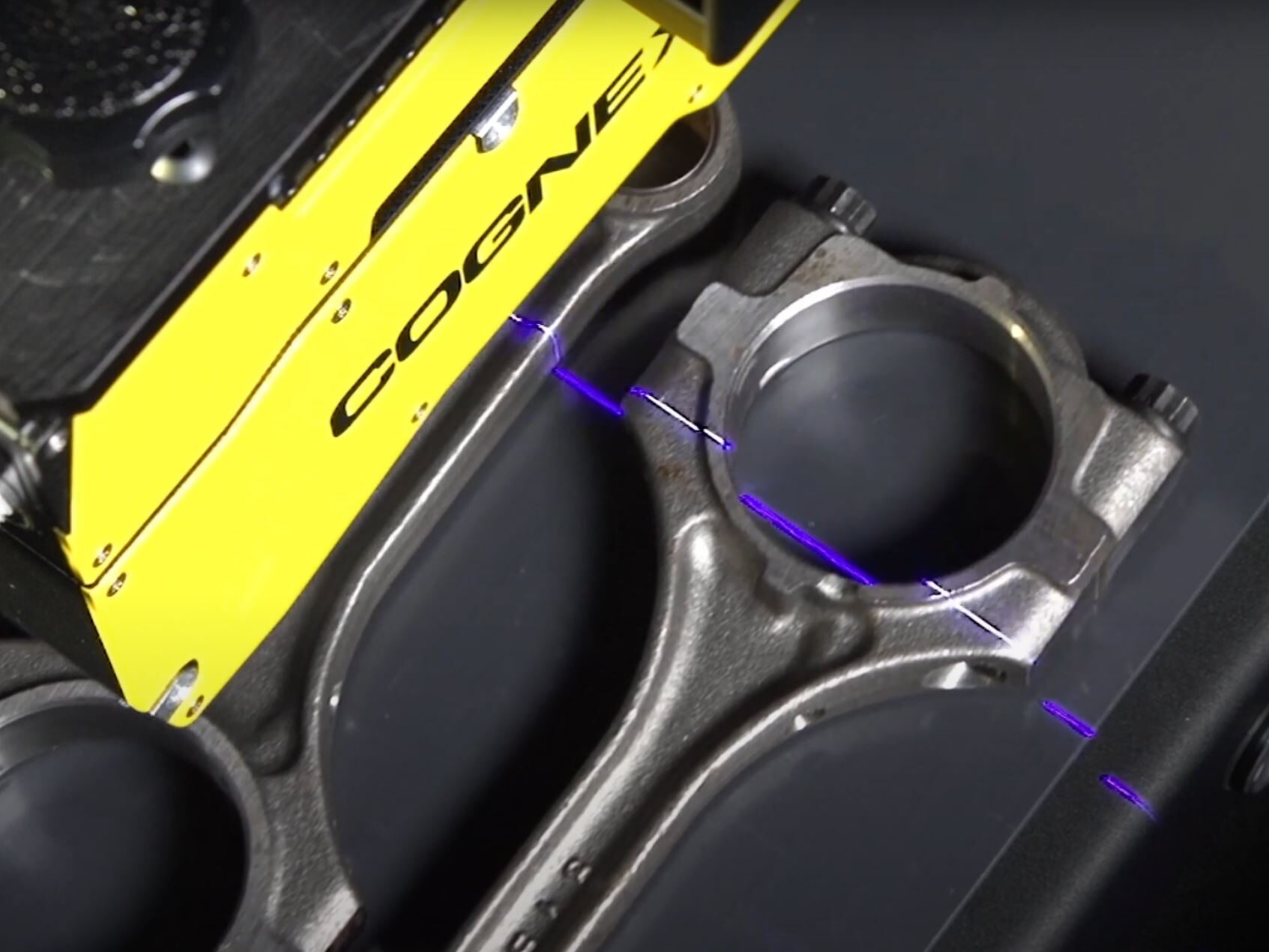

Inspection/Testing

The process of detecting defects, consistency through machine vision systems.

Remote Monitoring

Remote Monitoring (RMON) is a standard specification that facilitates the monitoring of network operational activities using remote devices known as monitors or probes.

Material Handling (MiR Pallet Jack)

The MiR1200 robotic pallet jack revolutionizes internal pallet transportation, automating detection, transport, and delivery of pallets up to 1200 kg at 1.5 m/s.

Proudly teaming up with

The possibilities for smart automation and robotics are endless

Lease an automation or robotic solution for as little as 78¢/hour

We believe you should have as much flexibility in financing your solution as our automation/robotic solutions deliver. That’s why many organizations choose to lease as it allows you to implement an automation solution at a low hourly cost.

Leasing lowers your financial barriers for investing in automation and gives you a near-immediate return on investment (ROI). Unlike an upfront capital investment, leasing becomes an operational expenditure instead of a fixed cost. Leasing allows you to get going faster to automate all those monotonous, repetitive, and often injury-prone manual material transportation processes and free your team up to work on other high-value tasks.